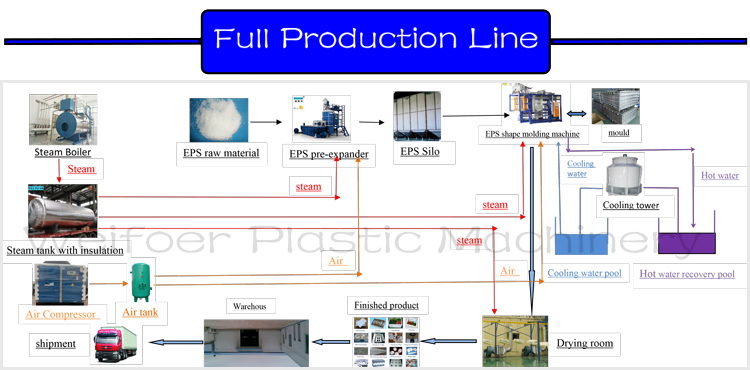

Introduction to machine function:

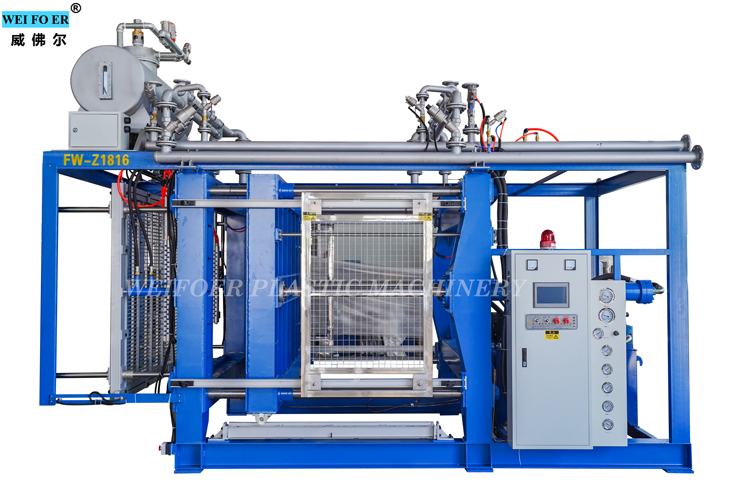

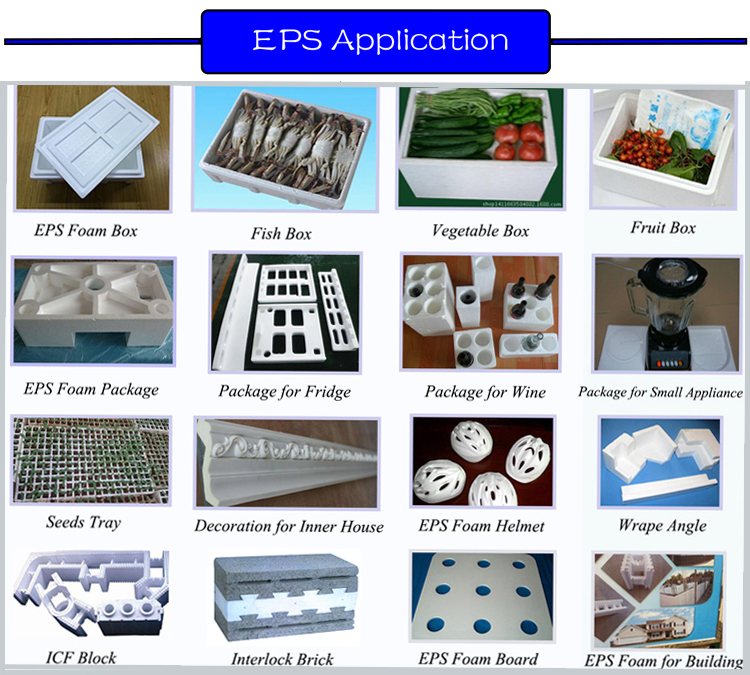

This machine adopts PLC and color touch screen, and adopts advanced molding technology to produce various shapes eps products, like fish box, fruit box, vegetable box, packaging for TV/refrigor/washing machine, seedling tray and so on. The vacuum system and hydraulic system can increase the molding speed and reduce the water cooling time, making the foam product lowest moisture content.

Main Features:

A. Machine structure:

1. The frame is welded byquality steel, high strength and good stability;

2. Rack failure annealed after welding heat treatment. Using imported CNC machining center. The underlying fine uses sand-blasting, galvanizing and the overall surface painted, high corrosion resistance;

3.Moving template guide and bearing separation, prolong the service life of the guide post;

B. Technique:

1.Three sewage pipe technology, the fixed mold, moving mold and vacuum systems are woking independently;

C. Operation:

1. Four kinds operating mode: automatic, semi-automatic, middle starting and manual;

2. Safety door has three kinds protection devices: safety door switch, pause switch and emergency stop; .

D. Electronic Control:

1. Controlled byprogrammable controller and color touch screen, easy to operate

2. The main parts(CPU template, touch screen, start parts, hydraulic parts, pumps, etc.) are all international and domestic famous brands;

3. Production control and management can be operated by computer,high degree of automatic,easy to operation and maintenance.

Model:FW-Z1816S Brand:WEIFOER Code:8477409000

This machine adopts PLC and color touch screen, and adopts advanced molding technology to produce various shapes eps products, like fish box, fruit box, vegetable box, packaging for TV/refrigor/washing machine, seedling tray and so on. The vacuum system and hydraulic system can increase the molding speed and reduce the water cooling time, making the foam product lowest moisture content.

Hangzhou Fuyang Fuwei EPS Machinery Co., Ltd, "Weifoer Plastic Machienry", a professional eps machine manufacturer with more than 30 years' experiance, in HANGZHOU, CHINA, since 1984. Our aim is "product top quality eps machine", our purpose is "one time cooperation, life-long friends", Look forward to working with you.

Our mail product has: eps pre-expander machine, eps shape molidng machine, eps block moulding machine, eps cutting machine, eps foam mould, silo, filling gun, ejector and all kinds spare parts for eps machine; auxilliary equipment has steam boile, stean tank with insulation, air compressor, air tank, cooling tower, water pump and so on. If you are interested in our eps machine, contact us. WhatsApp:+86-18257172586

Standard export packaging:

---Outer package: standard export wooden cases;

---Inner package: plastic paper or wrapped with stretch film and etc.

Shipping:

---By sea from Shanghai or Ningbo port;

---By train from Ningbo station;

---By truck from Kashgar, Urumuqi or other checkpoint

We adhere to the principle of "Quality First, One Cooperation, Life-long Friends". Our drivers have been sold to dozens of countries including Egypt, Turkey, Uzbekistan, Ukraine, Tajikistan, Ribane, Algeria, Mauritania, Peru, Taiwan, etc.