Model:FW-LX960-2 Brand:WEIFOER

Product Description

With continuous pre-expanders, the raw material feeding into the pre-expansion tank as well as the foaming process runs “continuously”

They are especially suitable for high material throughputs with almost the same densities all the way in a range of 12-30g/l.

1. Expansion chamber : made by quality stainless steels plate,.

2. 1st and 2nd passes are both workable.

3. Simple construction and thus low maintenance requirements.

4. Electric control, and valve system for adjustments of steam pressure, even density is achieved.

5. Simple and reliable operation.

6. Safety protection.

7. Drying system including fluidized bed drier is optional

Hangzhou Fuyang Fuwei EPS Machinery Co., Ltd, "Weifoer Plastic Machienry", a professional eps machine manufacturer with more than 30 years' experiance, in HANGZHOU, CHINA, since 1984. Our aim is "product top quality eps machine", our purpose is "one time cooperation, life-long friends", Look forward to working with you.

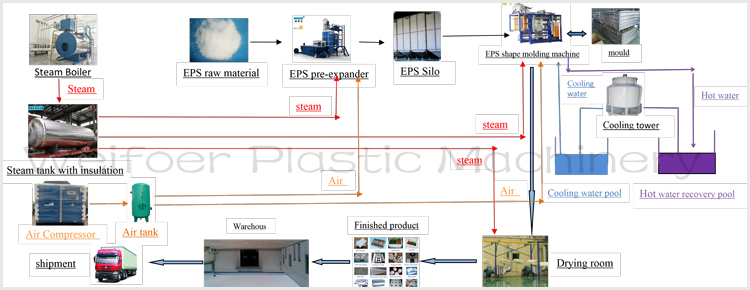

Our mail product has: eps pre-expander machine, eps shape molidng machine, eps block moulding machine, eps cutting machine, eps foam mould, silo, filling gun, ejector and all kinds spare parts for eps machine; auxilliary equipment has steam boile, stean tank with insulation, air compressor, air tank, cooling tower, water pump and so on. If you are interested in our eps machine, contact us. WhatsApp:+86-18257172586

Standard export packaging:

---Outer package: standard export wooden cases;

---Inner package: plastic paper or wrapped with stretch film and etc.

Shipping:

---By sea from Shanghai or Ningbo port;

---By train from Ningbo station;

---By truck from Kashgar, Urumuqi or other checkpoint

We adhere to the principle of "Quality First, One Cooperation, Life-long Friends". Our drivers have been sold to dozens of countries including Egypt, Turkey, Uzbekistan, Ukraine, Tajikistan, Ribane, Algeria, Mauritania, Peru, Taiwan, etc.