Main advantage:

1. Fully automatic and intelligent prodcution;

2. Human-machine cooperation, controlled by PLC and color touch screen, easy to operate;

3. Accurate density, high output and energy-saving

4. Smooth operation and stable

Function Description:

1. This machine accept PLC and color touch screen control, automatic feeding, automatic control barrel temperature and pressure, automatic sensor testing material;

2. The barrel is made by stainless steel, realize constant pressure foaming;

3. Control barrel temperature and pressure by Japanese imported pressure reducing valve and Germany imported proportional valve;

4. Using famous brand electrical components and pneumatic components, to ensure the machine running stable and smooth operation;

5. Using the photoelectric to control the expansion material volume,making the expansion density uniform;

6. Automatic discharge the material, by using fan to blow material, increase the discharge speed;

Model:FW-YF1600-2

Brand:WEIFOER

Code:8477800000

B.Main technical data

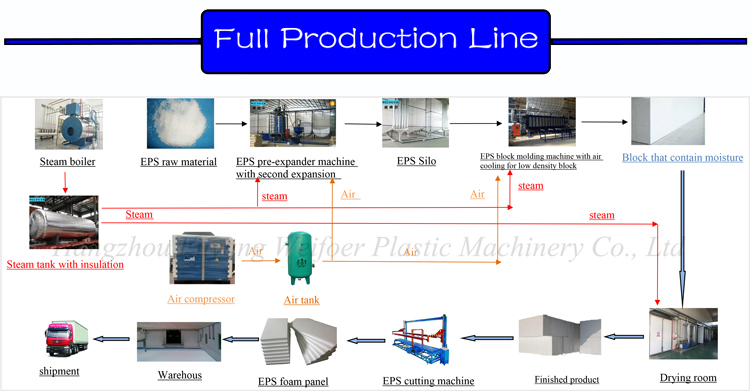

a---EPS pre-expander: it is used to expand the eps raw material to foamed beads; by second expansion, getting the lower density material and making

the light eps foam block.

Hangzhou Fuyang Fuwei EPS Machinery Co., Ltd, "Weifoer Plastic Machienry", a professional eps machine manufacturer, since 1984. Our mail product has: eps pre-expander machine, eps shape molidng machine, eps block moulding machine, eps cutting machine, eps foam mould, silo, filling gun, ejector and all kinds spare parts for eps machine; auxilliary equipment has steam boile, stean tank with insulation, air compressor, air tank, cooling tower, water pump and so on. If you are interested in our eps machine, contact us. WhatsApp:+86-18257172586

Standard export packaging:

---Outer package: standard export wooden cases;

---Inner package: plastic paper or wrapped with stretch film and etc.

Shipping:

---By sea from Shanghai or Ningbo port;

---By train from Ningbo station;

---By truck from Kashgar, Urumuqi or other checkpoint