Main Features:

1、with reduce pressure valve;

2、Double steam valves;

3、Pressure sensor and high frequency solenoid valve control the mould chamber pressure;

4、With material position rotary switch

Function description:

1. Machine structure:

All frame are welded onto 25mm steel plate with high machine legs.This greatly improves machine strength.

High machine legs are made by strong ''H'' type profile. It is easy for the client to install the machine (only prepare floor foundation).

2. Filling system:

Adopts normal pressure and pressurized filling. Material filling is controlled by level sensor with double rotation chamber discharge and has 66 filling outlets.

3. Steam system:

Adopts pressure sensor and high frequency solenoid valve. This greatly improves steam accuracyand reduces consumption.

4. Cooling system:

Big vacuum pump with vertical tank, installed at the bottom of the machine,making drainage smooth, high vacuum. All these keep very high efficiency, so thatvacuum cooling will be used as main coolinginstead of water cooling(normally water cooling will be set up only 8-12S), which will keep thewater content of product less than 10%.

5. Drainage system:

Increased large for inlet and outlet of mould,adopts1.5inch×8pcs inlet for steam, ensuring fast cycle time,1.5inch×8pcs outlet for drainage system, DN150 drainage pipe is controlled by butterfly valve, Together they greatly increase heating and drainage speed.

6. Control system:

Adopts PLC(LS,korea) and touch screen (MCGS) making operation easy.

All electronic components are from famous brands, which greatly improve the machines stability. All pressure regulation remotely controlled by the control box, the program also has many self-protection and alarm systems.

Model:FW-Z1715F Brand:WEIFOER

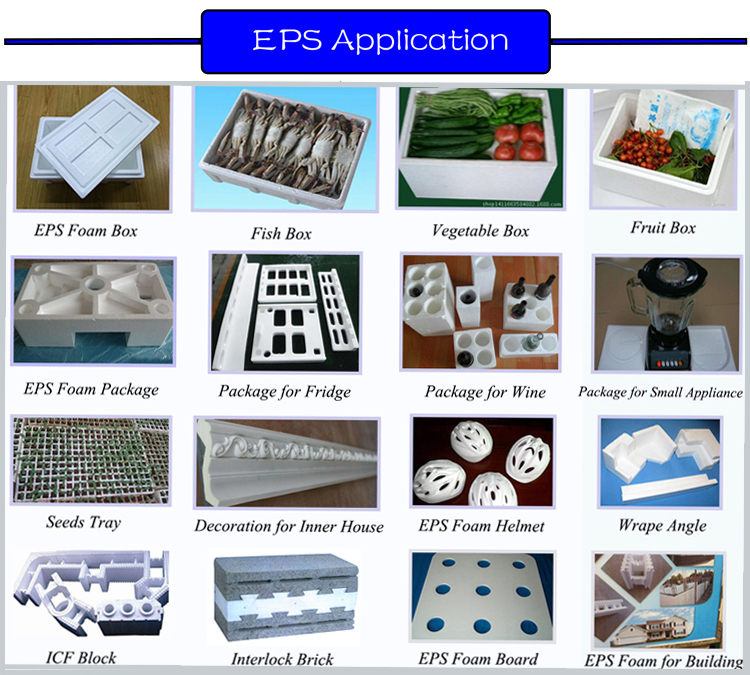

This machine adopts PLC and color touch screen, and adopts advanced molding technology to produce various shapes eps products, like fish box, fruit box, vegetable box, packaging for TV/refrigor/washing machine, seedling tray and so on. The vacuum system and hydraulic system can increase the molding speed and reduce the water cooling time, making the foam product lowest moisture content.

Hangzhou Fuyang Fuwei EPS Machinery Co., Ltd, "Weifoer Plastic Machienry", a professional eps machine manufacturer with more than 30 years' experiance, in HANGZHOU, CHINA, since 1984. Our aim is "product top quality eps machine", our purpose is "one time cooperation, life-long friends", Look forward to working with you.

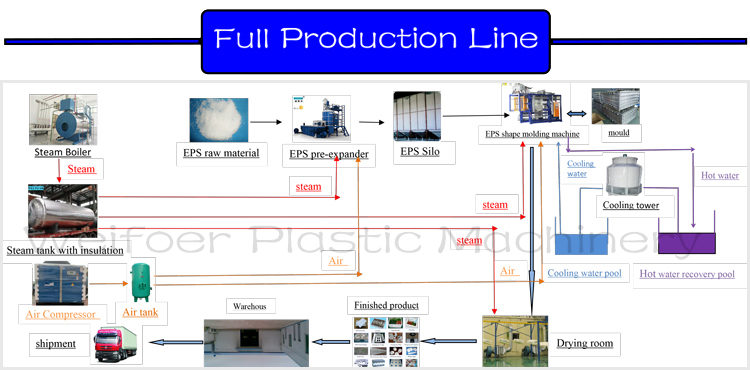

Our mail product has: eps pre-expander machine, eps shape molidng machine, eps block moulding machine, eps cutting machine, eps foam mould, silo, filling gun, ejector and all kinds spare parts for eps machine; auxilliary equipment has steam boile, stean tank with insulation, air compressor, air tank, cooling tower, water pump and so on. If you are interested in our eps machine, contact us. WhatsApp:+86-18257172586

Standard export packaging:

---Outer package: standard export wooden cases;

---Inner package: plastic paper or wrapped with stretch film and etc.

Shipping:

---By sea from Shanghai or Ningbo port;

---By train from Ningbo station;

---By truck from Kashgar, Urumuqi or other checkpoint

We adhere to the principle of "Quality First, One Cooperation, Life-long Friends". Our drivers have been sold to dozens of countries including Egypt, Turkey, Uzbekistan, Ukraine, Tajikistan, Ribane, Algeria, Mauritania, Peru, Taiwan, etc.